How the Painting Robot from ConBotics is Shaping the Future of the Construction Industry | Berlin Campus Charlottenburg

20/8/2024

The future of work will increasingly be shaped by the interfaces between humans and machines. Particularly in the construction industry, which is facing a shortage of skilled workers and increasing demands, it is clear that the interplay between artificial intelligence (AI) and robotics is crucial for progress. One notable example of this is ConBotics, an innovative startup from the Technical University of Berlin at the future-oriented Campus Charlottenburg. With the world’s lightest painting robot, the team wants to set new standards on German construction sites.

“A Painter’s Third Arm”

Founders Christian Amaya, Philipp Heyne, and David Franke began working on the “painter’s third arm” at the Technical University of Berlin as early as 2020, supported by funding such as the Berlin Startup Grant and the EXIST Startup Grant. Their innovative robotic system consists of a robot arm that mimics the human motion of spray painting and a mobile platform that is able to orient itself and move in its environment, enabling it to work largely autonomously. While the robot is painting, the painter can carry out other tasks and is physically relieved.

Image: ConBotics Founders: Philipp Heyne, Christian Amaya, and David Franke

Development in Collaboration with a Master Painter

After four years of intensive development work and close collaboration with Berlin master painter Robert Sachs, ConBotics has created a robotized tool that supports craft businesses in their daily work. The PainterRobot, which was specially designed for large-scale projects with a lot of monotonous wall and ceiling surfaces, not only offers precision and speed but also reduces paint consumption, which benefits the environment.

Image: ConBotics: Painting Robot with Robert Sachs

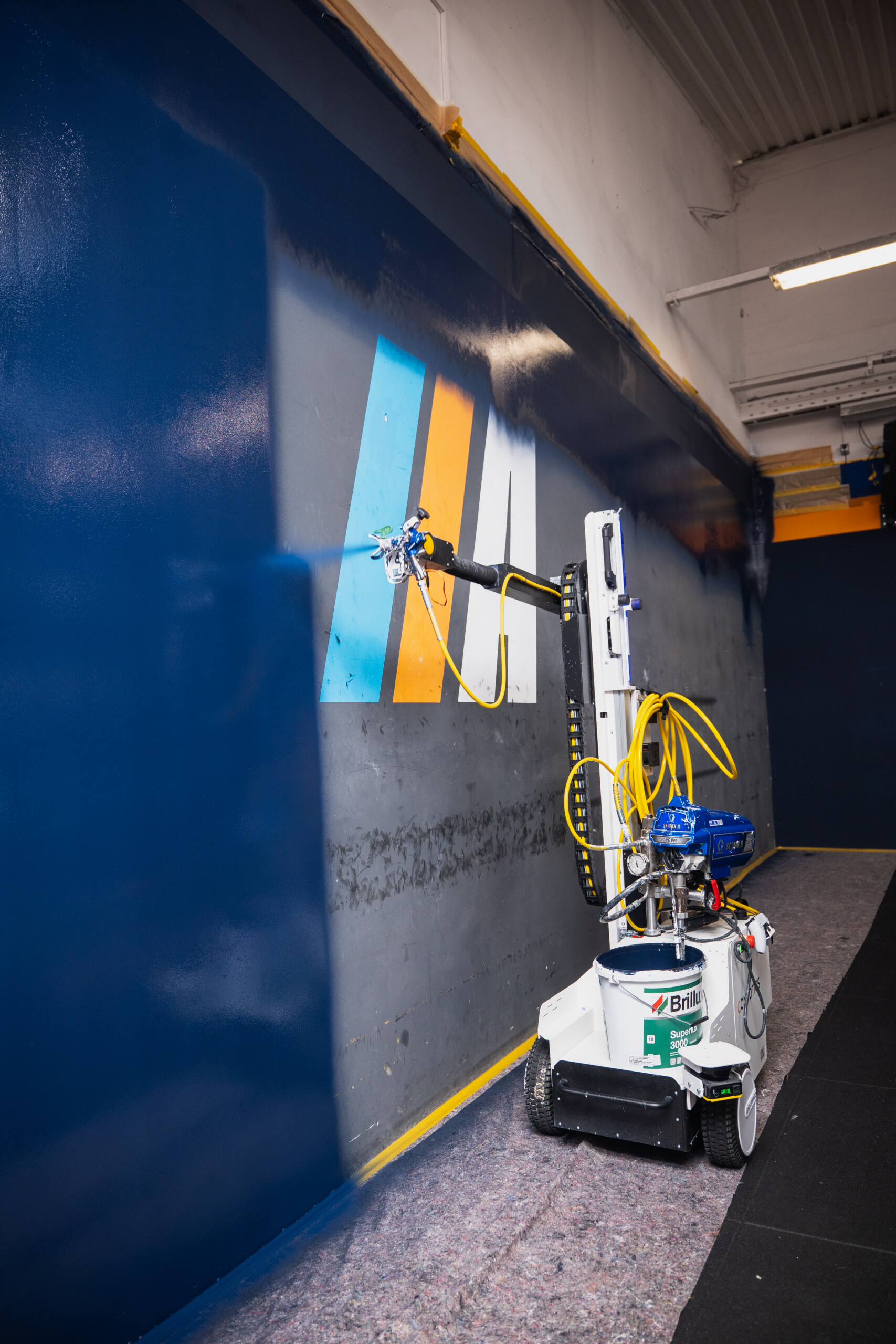

With the help of AI, the robot navigates autonomously through the room, recognizes windows and doors, and requires only minimal technical input from the tradespeople. The robot weighs only 60 kilograms, making it a practical and flexible helper on any construction site. Painting contractors can now rent it without high acquisition costs or risks. This is an important step in relieving the burden on much-needed skilled workers and efficiently completing projects despite a shortage of time and personnel.

Image: ConBotics

Image: ConBotics

ConBotics is setting a strong example for the future of the construction industry: a super team of humans and machines that works efficiently, sustainably, and flexibly to meet the challenges of the industry successfully.

See the Painting Robot in action here: Echtes Projekt mit dem MalerRoboter. Durchgeführt von ConBotics, Malerbetrieb Garms und Straßberger – YouTube

More about ConBotics: ConBotics | Malerroboter | Painting Robot | Robotic